|

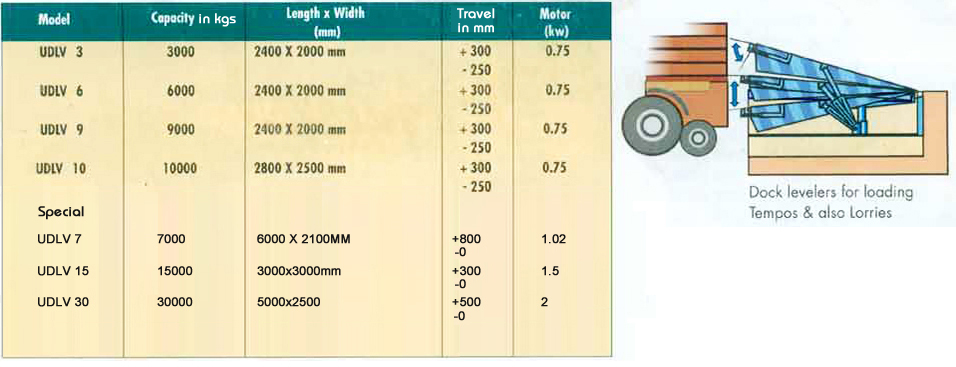

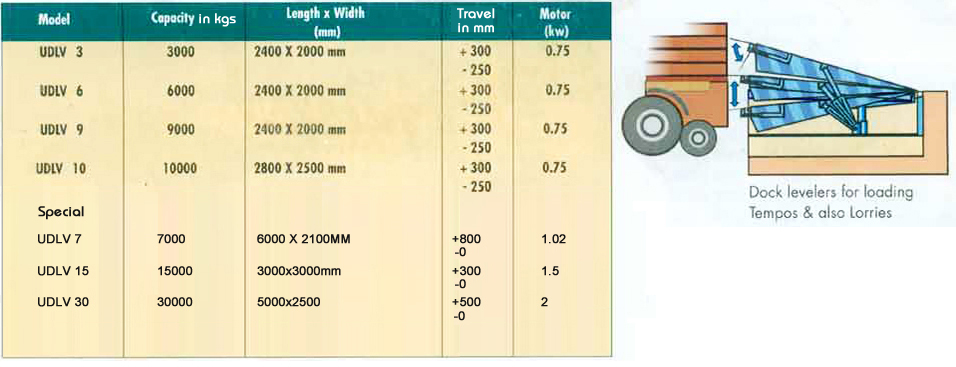

USHA has introduced Hydraulically operated Dock leveler which includes economically priced Hydraulically Dock leveler with manually operated lip and the Deluxe model with Hydraulically operated lip. In the standard design the dock has a travel of 500 mm above & 250 mm below horizontal level.

The standard platform sizes are 2400X 1800mm, 2500mm X 2000mm, 2730mm X 2000mm, 2730mm X 2100mm. USHA self supporting Dock leveler significantly improves your transport efficiency. It bridges the gap between loading platform & the different heights of lorries. A pit is made in loading Dock in which Dock leveler fits. Various loading capacities from 3 tons to 30 tons are available. Dock leveler can facilitate quick loading operations by allowing forklifts with materials to travel directly from loading platform into lorries / Containers.

The lifting operation is by Single or Double circuit 415 V AC Hydraulic power pack fitted inside the leveler or kept outside The controls are by Up/Down push button Pendant OR Hand Lever valve for trouble free operations.

While specifying Dock leveler care should be taken regarding max gradient (slope) of the Dock leveler. This should be suitable for the equipment e.g. Hydraulic stacker / Fork Lift which is to be used for loading operation. Where gradients are not suitable or too high, scissor type dock lifts will be more suitable.

|

|

|

|

| External Type Dock Leveler |

|

These are used where there is no space for making Pit in the dock. This can be mounted outside the warehouse & normally

have a fixed type lip. Fork lifts can be used to load the container.

Operation is Electro Hydraulic.

Length of the platform depends on the height of warehouse floor from road level and the gradient which the fork lift can climb with fall load. |

|

| Dock Bumpers |

|

These are rubber Bumpers for mounting in front of Dock to prevent truck damaging the Dock / Leveler while reversing. |

|

| Dock Bollards |

|

These are steel concrete column which are installed in front of dock lift to prevent damage to lift from lorries reversing for loading additionally rubber bumpers are mounted on these to prevent damage. |

|

|

| Truck Chocks |

|

These are used for placing in front of Truck tyres to prevent Accidents due to movement of Trucks during Loading / Unloading Operation And preventing fork lift accidents |

|

|

| Truck Positioning System |

|

|

This system consists of system of sensors, lights and motors. As the truck reverses different lights and hooters are operated to guide and warm the driver. |

|

|

| Truck Restraints |

| These are automated type in view of truck chocks can include truck chocks with sensor interlocked with dock leveller or a powered system to prevent truck tyres from moving during loading/unloading operations. Prevents dock accidents |

|

|

| Scissor Type Dock Lifts |

| Scissor type dock leveler are used when conventional dock leveler become too long to give the required gradient i.e the level difference between floor level (dock) & lorry is > 700 mm approximately. In case of pallet trucks & Powered stackers the gradient has to be minimum to avoid interference of stackers legs since ground clearance is less in these equipments. |